HCS® and GiHCS®

FEATURES

- 200 µm and 400 µm Step-index Hard Clad Silica Fiber

- 50 µm OM2 and 62.5 µm OM1 Graded-Index Hard Clad Silica Fiber

- Wide operating temperature range

- Resistance to abrasion, vibration, and industrial chemicals

- HCS extending distance and bandwidth of POF (Plastic Optical Fiber) Systems

- Superior crush, twist, tensile strength and flex performance

- Ideal for Broadcom Versatile Link, Industrial Ethernet, Fieldbus, and Power over Fiber (PoF)

- Indoor and outdoor use

RESOURCES

HCS

HCS® (Hard-Clad Silica) optical fiber is a, polymer coated problem-solving fiber system invented by us in the early years of the optical fiber industry. A proprietary polymer is applied to the pristine surface of pure, fused silica as we draw the glass down to its final, multimode step-index, optical fiber form. We then add additional buffer layers to improve chemical and abrasion resistance. This final step increases the finished diameter to a dimension that is easier for field-technicians to handle.

The result is an optical fiber that is optimized for use at the 650 and 850 nm wavelengths which are common in transceivers deployed in many industrial applications. The pure silica core is highly transparent. This makes HCS fiber suitable for use over a very broad range of optical wavelengths and in a variety of applications beyond data communications such as fiber optic sensors, spectroscopy and laser delivery. HCS optical fiber is mechanically strong and is uniquely suited to field connectorization in harsh environmental conditions.

The OFS polymer material can be applied to HCS optical fiber as either a cladding or a coating; it’s that versatile. For instance, when applied as a cladding, a thin layer surrounding the light carrying central core, the OFS polymer helps reflect most of the escaping light back into the core and along the length of the fiber. The result is a very strong optical fiber with low attenuation (light loss) and an extremely high core-to-clad ratio. This high core-to-clad ratio is important for reasons of efficiency and systems expense. By using a very thin cladding layer, light transmitting devices are connected to a large core area that efficiently couples more of the optical energy into and along the fiber. This enables systems designers to take advantage of lower cost transceivers and simplified connectors to minimize overall systems expense.

GiHCS

The rapid adoption of Industrial Ethernet has led to significant changes and new demands in industrial networking applications requiring the introduction of industrialized communications systems. Fast (100 Mb/sec) and Gigabit Ethernet (1000Mb/sec) data rates demand higher bandwidth and real-time, low-latency communications. The increasing use of intelligent electronic devices, utility-grade rugged IP routers, and Ethernet switches is driving IP-based communications on the production floor.

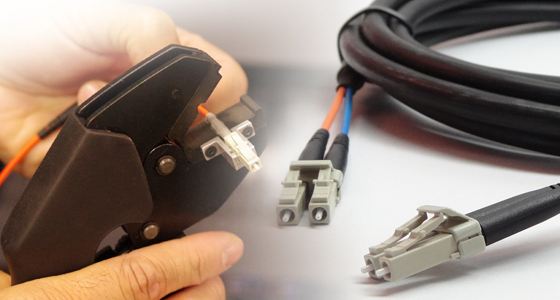

A high bandwidth, rugged, and reliable fiber cabling solution is indispensable for industrial networking as adoption of increased data rates emerges. To meet this need, OFS offers Graded-Index HCS® (GiHCS®) Optical Fiber in a Low Smoke Zero Halogen (LSZH) fiber optic cable construction and easy-to-use crimp and cleave LC connectors. Using OFS LC Crimp and Cleave simple hand tools, technicians can easily learn to install fiber connectors in industrial spaces. Taking just minutes to learn, field technicians can rapidly install new or repair damaged optical fiber cables without messy adhesives or tedious polishing procedures. Just “Crimp, Cleave and Leave.”

Crimp, Cleave and Leave.

OFS’ Crimp and Cleave technology helps make the typical 10-minute epoxy/polish process for installing fiber optic connectors a thing of the past. As part of an Industrial Networks solution, the LC Crimp and Cleave Connector takes center stage because of its compatibility with most common small form-factor pluggable (SFP) transceivers.